Printing cylinders

Suhan Flex Printing Cylinders Business has an advanced manufacturing unit for the production of Rotogravure Printing Cylinders, Flexo Plates & Flexo Printing Sleeves that carry out the intaglio printing process, which involves engraving & transfer of the image onto an image carrier. The image is engraved on Cylinders/ Flexo plates. To manufacture these cylinders, we carry out the whole process right from the steel base, copper plating, surface finishing, digital engraving, chrome plating and to final proof print.

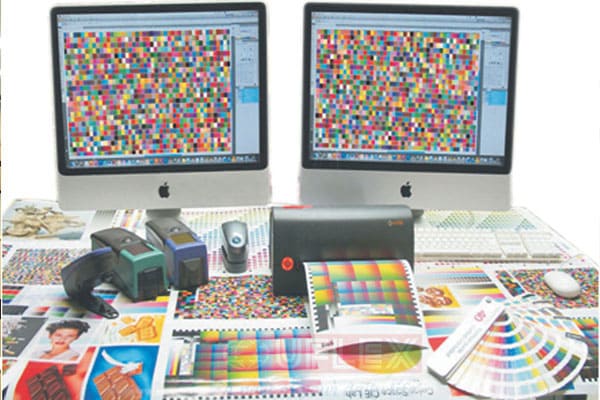

I) IN HOUSE DESIGNING:

In-house “CREATIVE Team…..

We offer one stop solution from Design to Print – traversing the complete life-cycle. A dedicated team of designers follow an extensive process to do an exceptionally creative job with immaculate finesse. We create designs for all kinds of Stock Keeping Units (SKUs)

II) PRE-PRESS:

The Digital Pre-press Department at UFlex uses a specialized packaging and planning software ART PRO & Pac Zed to meet all kinds of Gravure & Flexo printing requirements. The software is the last word in techniques like colour separation, trapping, barcode generation and Pantone. For optimum halftone results, the highly experienced and internationally trained professionals at the manufacturing facility spin their magic on colour calibrated monitors. Besides this, we have exclusive software specially deployed for a fine making-of wallpapers, wood grain and texture design cylinders. Furthermore, to achieve vibrant and rich colours, technology, Hexa-chrome is put in use.